In today’s industrial landscape, sustainability is a key focus for manufacturers seeking to reduce their environmental footprint while optimizing energy usage. Waste heat boilers play a crucial role in sustainable manufacturing by capturing and repurposing excess heat from industrial processes. These systems not only enhance energy efficiency but also contribute to cost savings and regulatory compliance.

One emerging trend in this sector is the integration of industrial electric boilers, which further enhance sustainability efforts by utilizing cleaner energy sources. This article explores the role of waste heat boilers in sustainable manufacturing, their benefits, and the synergy between waste heat recovery and industrial electric boilers.

Understanding Waste Heat Boilers

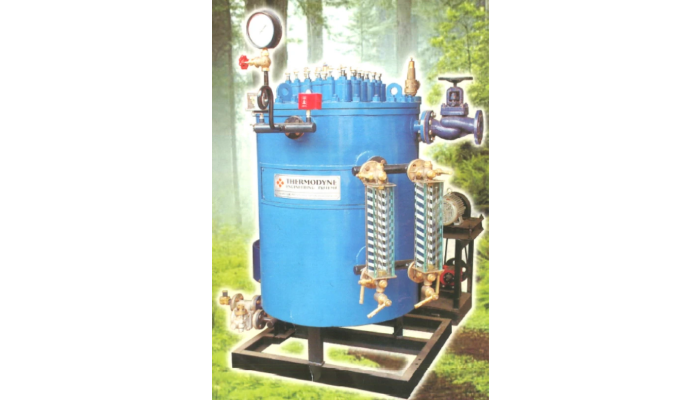

Waste heat fired boiler are specialized heat recovery systems designed to capture excess heat generated during industrial processes, such as metal refining, chemical production, and power generation. Instead of releasing this heat into the atmosphere, waste heat boilers convert it into useful steam or hot water, which can be repurposed for various applications.

These boilers are commonly used in industries such as:

- Chemical manufacturing

- Oil refining

- Steel production

- Food processing

- Cement and glass manufacturing

By integrating waste heat recovery, manufacturers can significantly reduce energy wastage, leading to improved overall efficiency and sustainability.

Benefits of Waste Heat Boilers in Sustainable Manufacturing

Energy Efficiency and Cost Savings

One of the primary benefits of waste heat boilers is their ability to improve energy efficiency. By capturing and reusing excess heat, industrial facilities can reduce their reliance on primary fuel sources. This results in lower fuel consumption and cost savings on energy bills.

For instance, in a conventional system, industrial processes generate substantial waste heat that dissipates into the environment. Waste heat boilers help recapture this heat and use it for processes such as heating water, generating steam, or even preheating combustion air for industrial furnaces. This leads to a more efficient use of available energy.

Lower Carbon Emissions

Sustainability in manufacturing is largely measured by carbon footprint reduction. Waste heat boilers contribute to lower greenhouse gas emissions by decreasing the demand for fossil fuel-based energy sources. As industries reduce their dependency on traditional fuels, they also lower the emissions associated with energy production.

By implementing waste heat recovery, companies can align with global environmental goals, such as the Paris Agreement, and meet stringent regulations set by local governments.

Improved Process Reliability and Performance

Waste heat boilers enhance operational stability by ensuring a consistent supply of energy. Since these systems utilize residual heat, they act as supplementary energy sources that provide backup during peak demand periods. This results in more reliable industrial operations with fewer fluctuations in energy supply.

Integration of Industrial Electric Boilers with Waste Heat Systems

What Are Industrial Electric Boilers?

Industrial electric boilers are heating systems that use electricity instead of fossil fuels to generate heat, steam, or hot water. These boilers are increasingly being adopted as industries transition toward greener and more sustainable energy solutions. Unlike traditional boilers, industrial electric boilers offer zero emissions and greater control over heating processes.

How do Industrial Electric Boilers Complement Waste Heat Boilers?

While waste heat boilers capture and repurpose excess heat, there are times when the recovered heat may not be sufficient to meet the full heating demand of an industrial facility. This is where industrial electric boilers come into play. They serve as an excellent complementary technology by providing additional heating when waste heat alone is inadequate.

For example:

- In manufacturing plants where waste heat recovery varies due to fluctuating production loads, industrial electric boilers can supplement heat during low-output periods.

- Facilities powered by renewable energy sources (such as solar or wind) can use electric boilers to ensure continuous operation without relying on fossil fuels.

- Electric boilers can improve overall plant efficiency by offering a clean and sustainable heating alternative, further reducing dependence on non-renewable energy sources.

Case Studies: Real-World Applications of Waste Heat Boilers and Industrial Electric Boilers

Steel Manufacturing Industry

A leading steel production plant integrated a waste heat boiler system to capture high-temperature flue gases from its blast furnaces. The recovered heat was used to generate steam, which powered various plant operations. Additionally, the facility installed industrial electric boilers to provide supplementary heat when waste heat availability fluctuated. This approach significantly reduced the plant’s natural gas consumption and carbon footprint.

Food Processing Industry

A large-scale food processing plant utilized a combination of waste heat boilers and industrial electric boilers to enhance its energy efficiency. The waste heat from baking ovens was captured and used for preheating water needed in food preparation. Industrial electric boilers ensured that the facility maintained optimal heating during downtime or low waste heat recovery periods. As a result, the plant cut its energy costs by 30% and achieved compliance with sustainable manufacturing guidelines.

The Future of Sustainable Manufacturing with Waste Heat and Industrial Electric Boilers

The integration of waste heat boilers and industrial electric boilers is expected to grow as industries continue their sustainability journey. Technological advancements, including smarter automation systems and AI-driven energy management, will further enhance the efficiency of these solutions.

Governments and industry regulators are also offering incentives for companies adopting sustainable energy solutions. By investing in waste heat recovery and electric boiler technologies, manufacturers can benefit from tax credits, rebates, and other financial support programs.

Conclusion

Waste heat boilers play a crucial role in sustainable manufacturing by reducing energy wastage, lowering carbon emissions, and improving process reliability. When combined with industrial electric boilers, these systems create a highly efficient, eco-friendly, and cost-effective solution for industrial heating needs.

By adopting waste heat recovery and electric boiler technologies, manufacturers can not only enhance operational efficiency but also contribute to a greener future. As industries move toward cleaner energy solutions, the integration of these technologies will be key to achieving long-term sustainability goals.

Fran Bullock, a literary explorer rooted in the charm of England, unearths stories that resonate with the echoes of history. With a quill dipped in nostalgia, she pens tales that bridge the past and present, weaving narratives that captivate the soul.