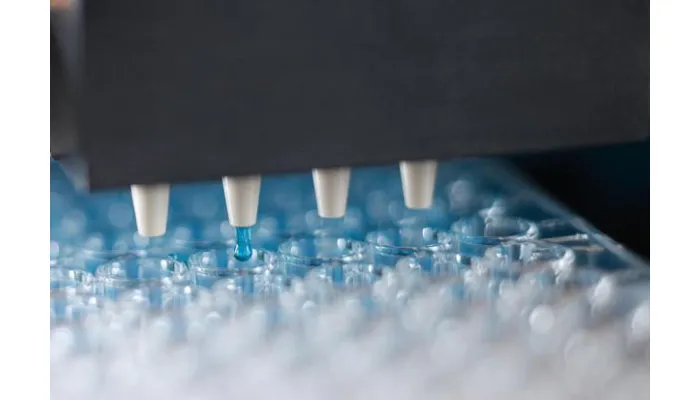

Assay automation brings many benefits like improved efficiency and reduced human error, but it also comes with several common challenges. Integration between new automated systems and existing equipment often causes data silos or workflow disruptions. Users may struggle due to insufficient training, making the learning curve steep during the shift from manual to automated processes. Managing large data volumes securely while ensuring regulatory compliance is another issue labs face. Staff resistance due to fear of change can hamper adoption, and maintenance neglect risks system reliability. Solutions involve selecting compatible, scalable systems, providing comprehensive training, proactive upkeep, and fostering open communication to support smoother transitions and better outcomes.

Challenges of Integrating New Automation with Existing Systems

Integrating new Assay automation equipment with existing legacy systems often presents significant challenges due to differences in data formats, communication protocols, and hardware interfaces. Many legacy instruments lack modern APIs or standardized connections, making seamless data exchange difficult without extensive customization and testing. This can lead to delays and errors during integration, as well as the risk of creating isolated data silos where information cannot flow freely between systems. Physical incompatibilities, such as mismatched ports or the need for special adapters, add another layer of complexity. Moreover, automation software from different vendors may have conflicting requirements or limited support, requiring detailed collaboration and documentation to resolve. Existing workflows built around older systems may be disrupted, forcing laboratories to reengineer processes to fit the new setup. Upgrading IT infrastructure might also be necessary to handle increased data loads or newer communication standards. Thorough testing before full deployment is crucial to avoid operational downtime and ensure that the integrated system functions reliably under real-world conditions. For example, a lab introducing a new automated liquid handler may find that its legacy plate readers do not communicate in the same protocol, requiring middleware development or manual data transfer steps, which can interrupt established workflows and reduce efficiency until fully resolved.

Training Needs and User Adaptation in Automated Assays

Automated assay systems introduce new software interfaces and hardware controls that can be complex for operators to master. Without sufficient training, users may misuse equipment or struggle with workflows, leading to higher error rates and increased downtime. A blend of hands-on practical sessions paired with theoretical instruction tends to improve knowledge retention and build operator confidence. Since staff learn at different speeds, training programs must be flexible to accommodate individual needs. Ongoing refresher courses are equally important to keep users updated on system changes and to address turnover. Transitioning from manual to automated processes often meets resistance, especially from those comfortable with traditional methods. Providing clear documentation, including quick-reference guides, empowers users to troubleshoot routine issues without delay. Training should not only cover daily operations but also emergency procedures to prepare users for unexpected situations. Encouraging feedback during training allows customization of sessions to fill knowledge gaps. Ultimately, well-trained users become more independent, reducing reliance on external support and enhancing overall lab efficiency.

Managing Large Data Sets and Ensuring Data Integrity

Automated assays generate vast amounts of data that require secure, scalable storage solutions capable of handling continuous influx without compromising accessibility. Each data point must be meticulously tracked with timestamps, sample IDs, and operator logs to maintain a clear record of its origin and handling. Ensuring data integrity involves implementing checksums and validation rules that detect errors early, preventing corrupted or incomplete results from affecting downstream analysis. Regulatory bodies mandate comprehensive audit trails that document data provenance and any modifications, making transparency essential for compliance. Regular backups and disaster recovery plans are critical to protect against data loss due to system failures or cyber threats. Real-time data monitoring tools can identify anomalies or instrument malfunctions promptly, allowing for swift interventions before errors compound. Integrating assay data with Laboratory Information Systems (LIS) facilitates centralized management, streamlining workflows and supporting data sharing across platforms. Strict access controls are necessary to prevent unauthorized viewing or tampering, preserving the trustworthiness of the dataset. Employing standardized data formats simplifies analysis and collaboration both within the lab and with external partners. Routine data reviews help maintain quality and assist in troubleshooting issues, ensuring reliable, reproducible assay outcomes throughout automated processes.

Overcoming Staff Resistance and Cultural Barriers

Resistance to assay automation often stems from fears of job loss or shifts in roles, which can create anxiety among staff. Addressing these concerns requires open and honest communication about the goals and benefits of automation early in the process. Involving employees from the start helps build trust and reduces skepticism. Emphasizing how automation takes over repetitive, mundane tasks rather than replacing people can improve acceptance. Offering training and skill development opportunities allows staff to see clear personal growth and new career paths, which further supports buy-in. Leadership must actively support these efforts with consistent messaging to reinforce positive attitudes. When concerns arise, addressing them openly prevents rumors and misinformation from spreading. Recognizing and rewarding those who adapt encourages ongoing engagement, while identifying change champions within teams promotes peer support. Ultimately, fostering a workplace culture that values learning and adaptability creates a smoother transition and helps staff feel part of the innovation rather than threatened by it. For example, a lab that involved its technicians in selecting automation tools and provided upskilling workshops saw faster acceptance and fewer disruptions during implementation.

Maintaining Reliability Through Regular System Care

Maintaining the reliability of assay automation systems depends heavily on regular and proactive care. Scheduled preventive maintenance is key to reducing unexpected breakdowns and minimizing costly downtime. Following vendor-recommended protocols not only keeps the system running smoothly but also ensures warranty compliance. Routine tasks like cleaning and calibration are essential for keeping instruments within their specified performance ranges, which directly impacts assay accuracy. Monitoring system performance metrics allows early detection of wear or faults before they escalate into major failures. Keeping an inventory of spare parts on hand helps avoid repair delays, which can disrupt lab schedules. Documenting all maintenance activities supports traceability and accountability, providing a clear record of system health and interventions. Training staff to perform basic upkeep tasks empowers them to prevent minor issues from growing, fostering a sense of ownership over equipment. Automated alerts for service reminders improve adherence to maintenance schedules, reducing the risk of missed upkeep. Collaborating closely with vendor service teams ensures expert support is available when needed and helps tailor maintenance plans to the lab’s specific usage patterns. Adjusting maintenance frequency based on actual system use optimizes reliability while controlling costs, making maintenance both efficient and effective.

Scalability Issues in Growing Assay Workloads

Initial automation setups often struggle to keep up as sample volumes increase, revealing limitations in system capacity. Many early designs lack modularity, which restricts adding new instruments or expanding functionalities without major disruptions. Software performance can also degrade when handling larger data sets, causing slowdowns or instability that affect throughput. As workloads grow, resource management becomes critical: reagents, consumables, and staffing levels must be adjusted to avoid shortages or bottlenecks. Interestingly, speeding up automated steps may simply shift delays to manual parts of the workflow, creating new bottlenecks elsewhere. Planning for future assay expansion during the initial procurement stage helps sidestep costly system upgrades later. Choosing flexible automation platforms that support easy reconfiguration enables labs to introduce new assays without rebuilding their entire setup. Integrating automation with inventory control and scheduling systems further supports smooth scaling by optimizing resource use and timing. Regularly assessing system capacity and performance allows early detection of scaling issues before they impact operations. Ultimately, balancing upfront costs with scalability ensures that automation investments continue to deliver efficiency gains as workloads grow.

Effective Troubleshooting for Complex Automation Errors

Errors in assay automation can stem from hardware failures, software glitches, or user mistakes, making troubleshooting a multi-layered challenge. To address this, labs must adopt systematic diagnostic procedures that isolate issues step-by-step, supported by clear protocols that guide operators through each stage. Detailed logging of error messages and system states is crucial, as it provides the context needed for root cause analysis. Encouraging open communication between operators, IT teams, and vendors accelerates problem resolution by pooling expertise. Training staff to recognize common error patterns empowers them to act quickly and confidently rather than waiting for external support. Monitoring tools play a key role in detecting subtle deviations in system performance early, often before a full failure occurs, enabling preventive action. When troubleshooting, fail-safe procedures help maintain minimal disruption to workflows, preserving sample integrity and data accuracy. Keeping documentation up-to-date ensures teams respond consistently to known issues, reducing guesswork. Regular reviews of incident reports reveal recurring problems and highlight areas for improvement. Additionally, investing in remote support allows vendors to diagnose and fix issues without the delay of on-site visits, cutting downtime significantly. For example, if an automated liquid handler shows inconsistent pipetting volumes, system logs combined with operator observations and vendor input can quickly pinpoint whether the problem lies in hardware calibration, software commands, or user setup errors, enabling a targeted fix rather than broad trial and error.

Preserving Manual Skills Alongside Automation

While automation boosts efficiency and consistency in assays, preserving manual skills remains essential for laboratory resilience. Manual proficiency is critical when troubleshooting unexpected issues or during system downtime, allowing staff to maintain workflow continuity. Training programs should continue to emphasize key manual techniques to ensure staff can confidently switch between automated and manual workflows as assay demands change. Documenting legacy methods not only safeguards institutional knowledge but also supports validation and comparison of automated results. Hands-on skills deepen understanding of assay chemistry and context, fostering greater engagement with the science beyond automated processes. Encouraging job rotation helps keep manual and automated competencies balanced across the team, preventing skill gaps. Maintaining manual methods also provides a valuable backup during equipment failures and supports a more flexible, capable laboratory environment that balances automation efficiency with practical expertise.

Frequently Asked Questions

1. What are the main technical issues faced during assay automation implementation?

Technical challenges often include equipment calibration errors, inconsistent sample handling, and software integration problems. These can lead to data variability and require careful troubleshooting and validation practices to ensure consistent performance.

2. How can data quality be maintained when automating complex assays?

Maintaining data quality involves regular instrument maintenance, thorough validation protocols, and using controls to detect errors early. Automating steps like sample preparation and detection with precise timing also helps reduce variability and improve reproducibility.

3. What strategies help in managing workflow interruptions caused by assay automation failures?

Having backup systems, clear error alert protocols, and rapid troubleshooting steps are crucial. Training staff to identify and resolve common issues quickly minimizes downtime, while scheduled maintenance prevents unexpected failures in the automated workflow.

4. How do compatibility issues between assay reagents and automation platforms get resolved?

Compatibility problems can be addressed by selecting reagents validated for the specific automation system, optimizing protocols for user-specific conditions, and performing pilot runs. Collaborating with suppliers and using flexible software settings also help tailor processes to achieve reliable results.

5. What are effective solutions to reduce contamination risks in automated assays?

Reducing contamination involves using disposable tips or cleaning protocols between runs, designing workflows to minimize open handling, and maintaining a clean environment. Regular decontamination of equipment and monitoring for cross-contamination support accurate and trustworthy assay results.

TL;DR Assay automation improves lab productivity and reduces errors but comes with challenges like integrating new systems, training staff, managing large data, and handling cultural resistance. To overcome these issues, labs should focus on seamless system compatibility, ongoing user training, proactive maintenance, and scalable solutions. Preserving manual skills and adapting workflows also help ensure smooth transitions. With careful planning and support, automation can deliver faster results, cost savings, and better lab-clinical integration.

Mary Burns is a dedicated writer focusing on health and fitness topics. With a passion for promoting wellness and vitality, Mary shares her knowledge and expertise through engaging and informative blog posts.